What causes variation in the color of traditional collagenase products?

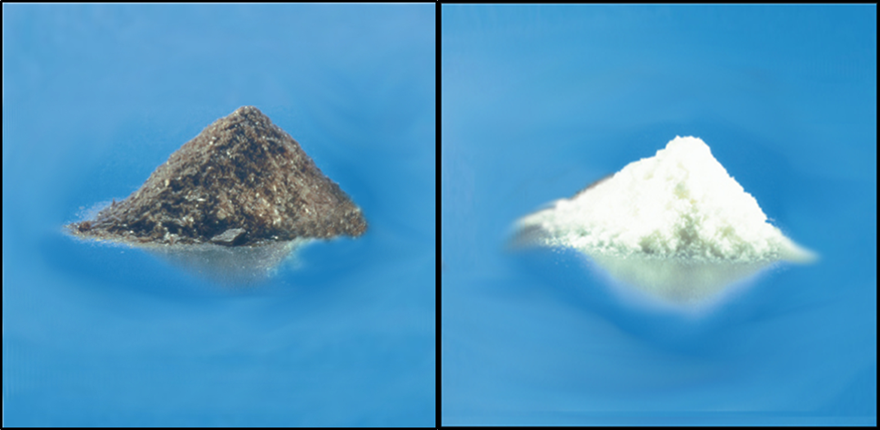

Traditional collagenase products can range in color from a light tan to dark brown. Color is directly influenced by the collagenase manufacturing process. Collagenases and neutral proteases are the key enzymes in these products principally responsible for degrading extracellular matrix and in turn, releasing cells from tissue. These key enzymes are colorless after purification, leading to the question…

What causes the dark color in crude collagenase?

The starting material used to prepare all Clostridium histolyticum collagenase products is supernatant obtained from anaerobic culture of C. histolyticum. Collagenase manufacturers inoculate pure strains of C. histolyticum into media containing animal proteins. During anaerobic fermentation a major byproduct is biopigment, which is responsible for the dark color of collagenase. If the culture supernatant is minimally processed (i.e., crude collagenase), the product has a brown-black color and the key enzymes identified above are < 10% (w/w) of the dry weight of the protein. C. histolyticum releases a wide variety of enzymes during culture, reflecting its role in nature as a saprophyte that breaks down organic matter to generate nutrients for sustenance and growth. The activity of key and other “contaminating” enzymes will vary, depending upon fermentation conditions. This variability in enzyme activity led many suppliers to offer lot qualification programs, enabling users to assess the performance of specific lots of product in their cell isolation procedure prior to purchase of larger amounts of enzyme.

Does lighter color correlate with improved lot to lot consistency?

Manufacturers of crude collagenase responded to requests for higher collagenase activity (per gram) by performing additional purification steps to enrich collagenase activity. This enrichment usually increases the percentage of key enzymes in the product, reduces the amount of biopigment, often yielding products with a light tan to light brown color. However, the biochemical characteristics of the key enzymes remain unknown with these enzymes comprising < 20% of the final product mass. Miscellaneous biochemical components and contaminating enzymes remain in the product. Lot qualification is usually required to verify performance.

What are key characteristics of traditional collagenase products?

The table below summarizes correlation of color with estimated percentage (w/w) of key enzymes. Representative products are listed for each collagenase product category.

Product Category |

Color |

% w/w Key Enzymes |

Representative Products |

Crude Collagenase |

Brown to black | 3-8% |

Types 1,2, 3, 4 Types I, Ia, II, IV, V, VIII Types A, B, C, D, H |

Enriched Collagenase |

Light tan to dark brown | 5-20% |

Type 5 Type XI Type P |

The variability inherent in the C. histolyticum fermentation process is the reason why each lot of crude or enriched collagenase product is unique. This is not surprising to users who routinely qualify new lots of crude collagenase prior to routine use in their cell isolation processes.

If you are interested in learning more about the limitations of traditional collagenase products, you can view a 33 minute video of a tech talk by Bob McCarthy at the 2015 American Cell Biology meeting entitled “Collagenase: moving from a black box to transparent knowledge” or download a copy of the White Paper entitled “Lot qualification: a common but costly pathway to select collagenase products for cell isolation. What are the known unknowns when using collagenase products?”